While salt was more or less discovered in Manistee, sand, on the other hand, was an abundant problem that residents of the city have had to, more or less, endure. In the past, the area’s sand dunes gave the city a unique reputation for being pretty to look at but also riddled with a nuisance that was difficult to eliminate. As the town grewand more buildings were constructed, the sand dunes became a challenge as sand was constantly drifting through various neighborhoods and blocking city streets. South of the Manistee River Channel, the large sand dune that was given the moniker “Creeping Joe” was so large and the sand so vast that area residents had to put up barriers in order to stop the sand from blowing on their property.

Meanwhile, on the north side of the city limits, a small neighborhood was even given the name “Jerusalem” because of the desert-like appearance of its environs. It was also said that up until the 1920s, no automobile had ever been able to drive through Manistee’s “Jerusalem” and, in addition, that a new paint job on a house on the Northside would only last three to four years at best because of the constant blowing sand.

Amid the turn of the 20th Century, various means were taken to combat the ongoing sand problem. In 1904, the Manistee Brick Company was incorporated and began taking the area’s sand and making it into material used for bricks. While many buildings in Manistee were built using this brick, the quality of the finished product was questionable and after ten years, the factory ceased production.

By the early 1920s, sand began being loaded and shipped via railcar to the Atlantic seaboard where it was used in various East Coast foundries. By the later part of the decade, companies such as the Hubbell Sand Company and the Manistee Sand & Dock Company were formed to collect, load, and ship the sand either by train or by vessel.

In 1930, the Manistee Sand & Dock Company merged with the Western Michigan Sand and Fuel Company of Muskegon and the Crescent Sand & Fuel Company of Port Crescent to form a new corporation named the Sand Products Corporation. During that time the Ford Motor Company also began hauling out a quarter of a million tons of sand per year to use in their factories.

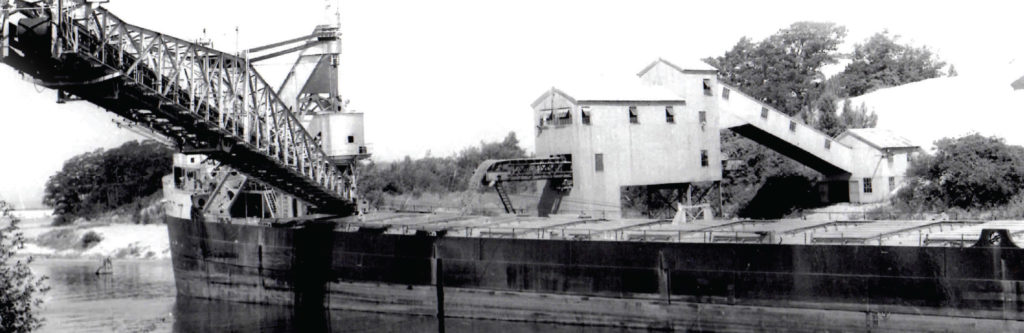

Ultimately, the Sand Products Corporation became the chief excavator of sand in Manistee and left an impression on many long-time residents and visitors alike who recall the big sand elevator located in the Manistee River Channel that was used to load large quantities of sand onto lake vessels. Another permanent fixture for many years was the lengthy conveyor system located on the north side of the city limits that allowed workers a more convenient way to load and unload sand.

Sand Products continued to mine sand in Manistee until the early 1970s when operations in the area ceased for good.

RELATED STORIES

Much like food without salt or a beach without sand, Manistee would not have been the same if it were not for the significant roles that both salt and sand have played within the confines of the area’s distinct and exceptional past.

THRIVING TODAY…

Today’s industry has a great impact on the local economy. Large employers like Morton Salt, Packaging Corporation of America, Tondu Corporation, Martin Marietta and Rieth-Riley have been heavily involved in the community from many aspects. Here are some of the profiles of these industrial leaders that are so important to our area.

Packaging Corporation of America (PCA) is a world class producer of corrugated products. The Filer Mill produces approximately 1240 tons per day of corrugating medium, the fluted middle layer of a box. In this process the mill recycles over 500 tons per day of old corrugated boxes and other paper products. In addition, one of the country’s largest anaerobic digesters combine for a green footprint.

The Filer Mill has a long history on the current site. A lumber mill was established in 1877, and the first paper machine started up in 1923. PCA continues to invest in the facility and keep pace with technological developments. The local workforce consists of 315 full-time employees, with an annual payroll of $35 million. The mill also contributes $952,000 in local property taxes.

Noron Composite Technologies, a fiberglass specialties company, is owned and operated by brothers Ronnie and Charles Melchert and has been in business since 1986. They produce fiberglass molds, models and parts for the automotive, RV and boating industries. New production lines include pylons for the food industry, restaurant seats for major food chains, outdoor planters and tables. Noron has also recently purchased Virtual Rocks of Northport, Mich.

The company credits the enthusiasm and dedication of their employees for the growth and success of their business. For more information visit www.noroncomposites.com

Rieth-Riley is a company that is 98 years old, serving the Michigan and Indiana areas, is 100% employee owned and provides materials for Asphalt paving. The deep-water port and rail system is major reason this business located in Manistee in early 2000s.

I remember going on a tour through the Morton Salt factory in the 1950’s. I remember the mountains of white salt and the little round containers of salt that they handed out. I was very young, but I remember it well.

Great articles. I was born in Manistee and lived my entire life in Manistee County. Really enjoy learning all I can about this beautiful area.